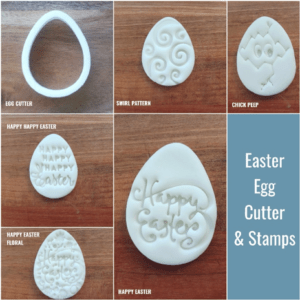

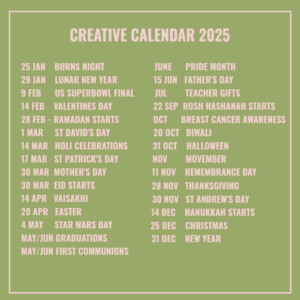

You’ll be aware that, if you’re familiar with SED Developments, we’re a micro-business printing and selling cookie cutters, fondant icing stamps, cake stencils and sometimes vintage car parts. How random is that? Even more random is how popular it all is. But of course the world of additive manufacturing – if we’re going to be proper – is much more complex than that. So this blog is by way of a look at where 3D printing is now – and the future of 3D printing.

The Wohlers Report

The what report I hear you cry. Yeah – we know. Stick with us. This report is as long-awaited by the additive manufacturing world as Christmas is by your average 5 yr old. The reason being that it’s the thing that 3D printing experts and followers use to get their digit on the industry’s pulse.

Back in 2019, as reported by Forbes in this article, the Wohlers report wiped down its crystal ball and predicted that spending on 3D printing products and services would hit $15.8 billion in 2020. They further posited an increase in this spending to $23.9 billion in 2022, leaping to $35.6 billion by 2024. Of course, this was all pre-pandemic 2020 so these predictions may well have gone awry. Even so – we’ve seen the future and it’s not orange. But it IS 3D.

Back to the future

So, the future continues apace then with 3D printing. In all aspects:

- Improved 3D printing technology

- Better quality of parts

- Greater accuracy

- And an expansion of materials available to work with

We’ve talked before about the areas with 3D printing involvement. They’re many and varied and include electric cars, fashion, food and the automotive industry in general. Then there’s the bio stuff: dental, heart replacement, eye care and more. Not forgetting custom items.

All these things will become more versatile in the materials they can use. Think here about nylon, chopped carbon fibre, various metals and super alloys. And that surely increases the capacity for use in different areas?

So what’s hot to look out for?

- A step – or four wheels – to tackling carbon emissions is Olli the self-driving bus. Not only is it 3D printed almost in its entirety but it’s electric too. It’s capable of carrying 8 people, reaching 25 MPH an covering a 100 mile on a single charge.

As this article from the 3D printing says, the development of Olli is a significant step in moving autonomous technology forward.

- Homes under the hammer – or off the printer? Apis Cor is the first company to develop specialized equipment for 3D printing in the construction industry. They recently 3D printed a 2-storey administrative building – the biggest building ever 3D printed on-site. Watch the magic happen on this time-lapse YouTube video.

- Prosthetics & Bioprinting – Yeah, we know, 3D printing in these areas have been going on for a while. In fact, if you’re paying attention, you’ll know that we’ve already written about this area of additive manufacturing in this blog about philanthropic 3D printing.

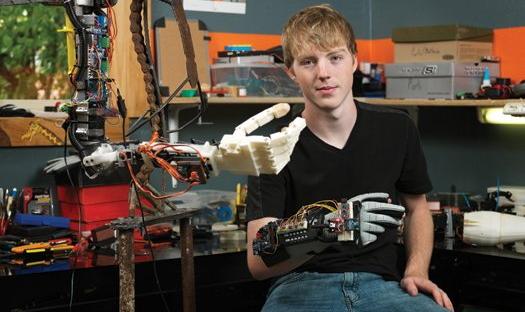

So why are we mentioning it again? Well, 23 yr old Easton LaChappelle – nicknamed ‘the next Elon Musk’ by Tony Robbins – is no ordinary entrepreneur.

At the tender of 14, he built his first working robotic hand with Lego bricks, fishing wire and tubing. Now, at a still pretty tender change, Easton is continuing his experimentation with making prosthetic devices using affordable 3D printing he’s making impressive progress.

In June 2017, LaChappelle put the first robotic arm his company made on a 10-year-old girl, from Florida called Momo, born minus a right forearm and hand.

Using scans, LaChappelle, made the prosthetic a mirror image of Momo’s left arm – right down to length and width of her fingers. Thanks to colour printing of the devices, Momo’s new arm even matches her skin tone.

Bioprinting is the art ofputting human cells into a hydrogel coating, something like the filament we use in our 3D printers. Already people are creating skin, cartilage and even, maybe, replacement hearts. Indeed, to this end, Cellink have developed a 3D printer helping researchers. Multidisciplinary research taking place at the Wyss Institute has led to the development of method of a multi-material 3D bio printing technique. With this method, scientists are generating vascularized tissues composed of living human cells almost ten-times thicker than tissues engineered up until now. What’s more these tissues can sustain their architecture and function for close on six weeks.

Democratization of 3D printing

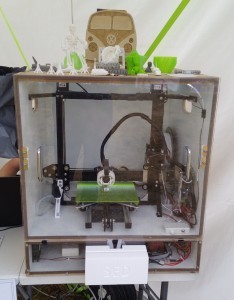

Want do we mean by that? Well we’ve read several articles now, including one from All3DP that shows more of the effects of 3D printing in the domestic context. By which we mean that more and more homes will have one. Or several in our case!

ALL3DP drew a comparison with the Internet. Back in the 1990s the Internet was a place for the nerds of this world. The rest of us dismissed it with a ‘Pah – it’ll never catch on.’ What a mistaka to makea! The rest, as we know all too well, is history. The Internet, and with it the World Wide Web, democratized information and how we access it. Google became a verb – as in ‘what time is that coffee shop open?’ ‘I’ll Google it’. And most of us are desolate without our smart phones clutched in our hot little hands.

The upshot of this democratization? The opening up of 3D printing to the masses, will spark an outpouring of creativity. Many of us will learn to make and create and replace items in our homes from clothes to washing machine parts.

Additive manufacturing can only advance. With that advancement the world of 3D printing becomes more than a filament of our imagination …